30%

less time to bring new new products to market

30%

increase in your capacity for innovation

15%

savings on new products development

Understanding PLM in 2 minutes

Explore the benefits of Visiativ PLM in this 2-minute video.

Promote product innovation and standardized processes

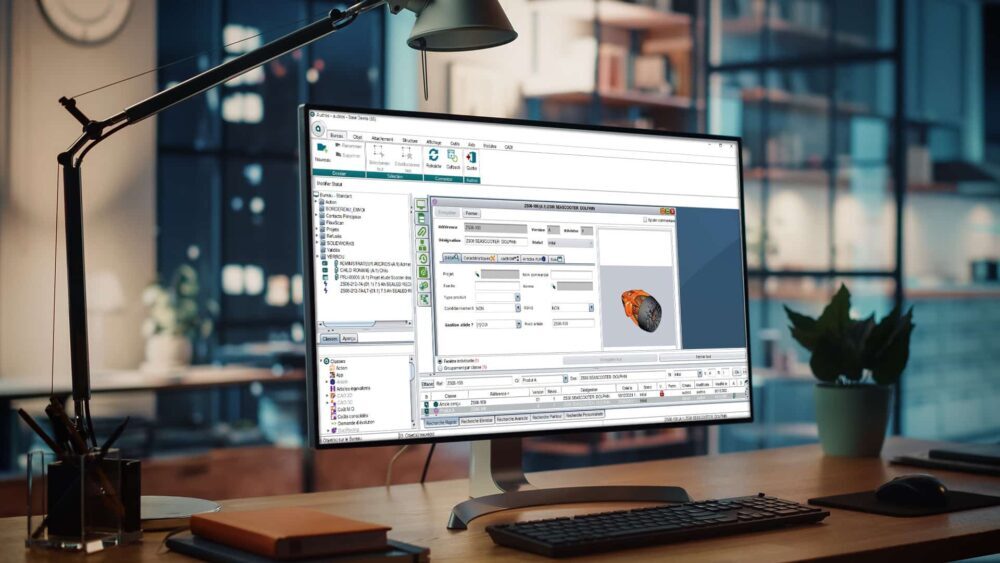

The Visiativ PLM range offers a multi-CAD PDM solution that provides a single document repository for product data, providing fast and secure access to all documents, version history and traceability of changes.

Visiativ PLM connects to all major CAD systems including SOLIDWORKS, CATIA, Creo, Inventor and more, enabling designers to carry out detailed studies on and definition of your products.

Your design team’s productivity will skyrocket thanks to effective collaboration and faster functional validation of your product designs.

Rappelez-moi

R&D to production in no time

The Visiativ PLM range connects your processes from R&D and design to production, purchasing and more.

Your design data is managed in departmental-specific layouts: Electrical BOMs and CAD BOM’s combine to become your manufacturing BOM, which can adapt to purchasing and production constraints by synchronizing with your ERP tool.

Moving from R&D to full production is simplified and manufacturing files are anticipated, with instruction sheets and operating procedures accessible to all stakeholders throughout the process.

Rappelez-moi

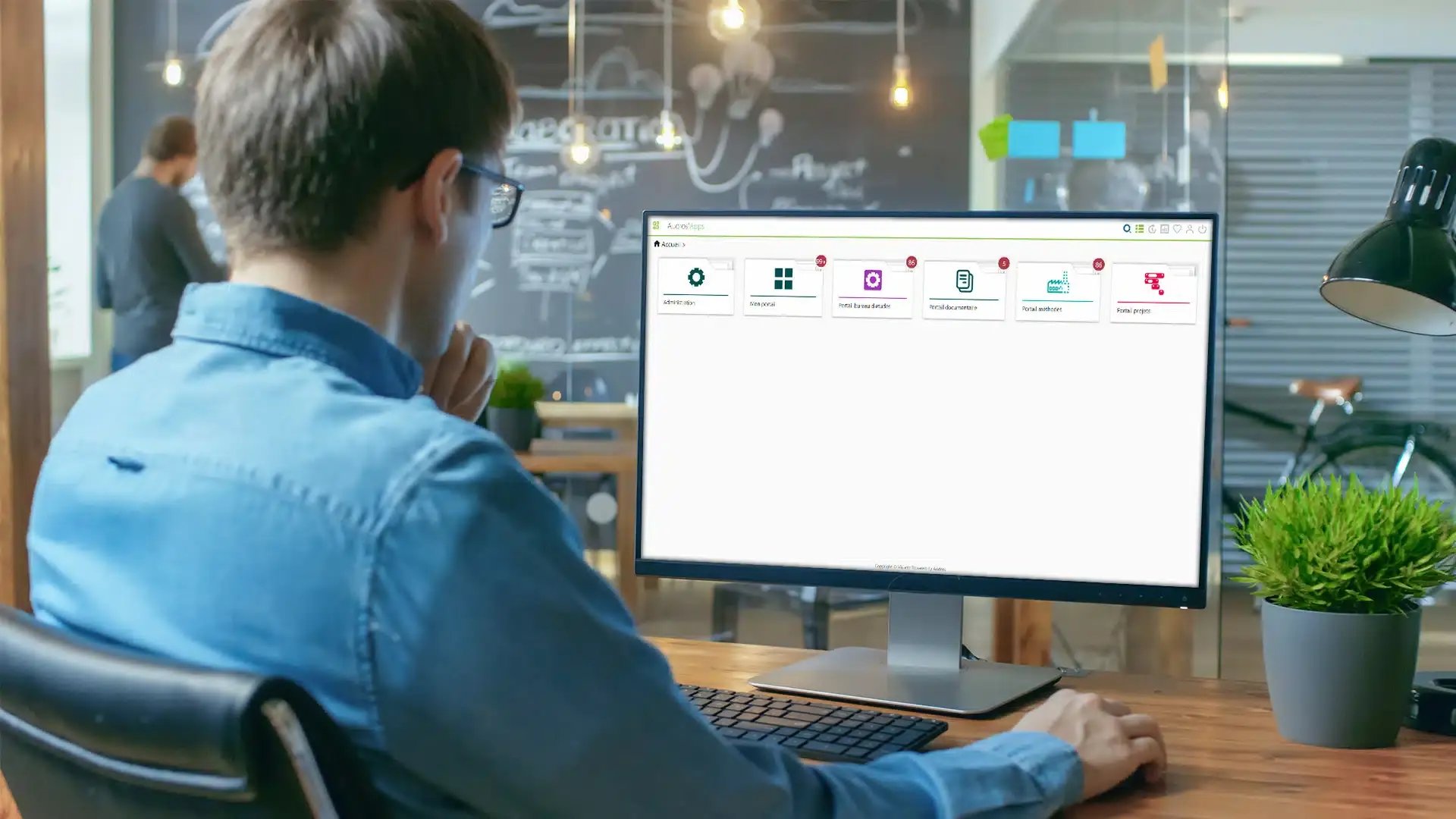

Simplified project management

Increase the success rate of your projects by making it easier to gather information, particularly on constraints and requirements. Project progress is easily shared with customers, external suppliers, and internal, multi-disciplinary, teams.

Visiativ PLM’s simplified planning tools improve the management of milestones and deliverables, and will also help you to monitor budgets with ease.

“Since we implemented Visiativ PLM at Latecoère Services, the preparation time for technical files has been reduced from 1.5 days to 2 hours! With CATIA and Pro/E connectors, our designers can work together on the same CAD project and share information in real time, from anywhere in the company.” Christophe Jaques, CAD Development Manager.

Rappelez-moi

Visiativ PLM benefits

Time Saving

PLM focuses on managing the interdependence between product components and the overall product environment.

By centralising all product information for the entire organisation, PLM ensures that everyone involved has access to the most up-to-date and accurate data, without having to waste time searching for info. This centralised data repository eliminates redundancies, reduces errors and improves collaboration between teams within your company.

Faster Development

Meet your deadlines faster than ever before thanks to:

- Technical data management

- Provision of technical drawings

- Management of production worksheets, processes and instructions

- Environmental standards and product impact management

- Simplified BOM management (XBOM)

- BOM to ERP data exchange

Automation

Why do all the hard work when Visiativ PLM can do all this?

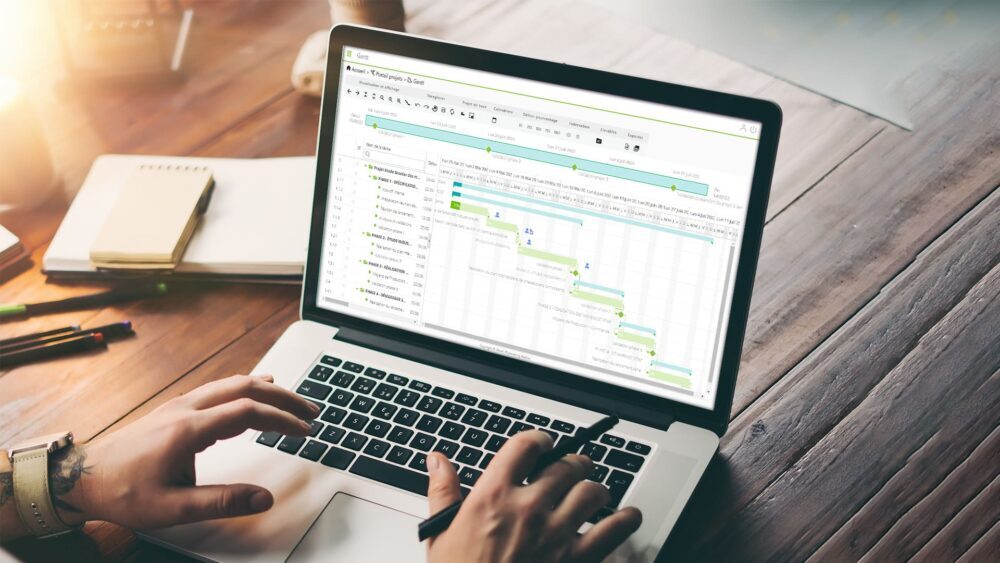

- Project, structure and resource management

- Action (Kanban), task and phase management, Gantt charts

- Project performance analysis

- Full GED document management

- Document exchange with your ERP tool

- Forms management with office documents

- Automatic filing from Windows

Resource Optimization

Integration between PLM and ERP (Enterprise Resource Planning) enables a seamless exchange of data between these two critical systems. When PLM and ERP work together, it provides better visibility of business processes, enabling more informed decision-making.

The unified management of technical data by PLM improves the performance of ERP, optimising the management of flows for manufacturing and logistics. This integration also reduces errors, improves productivity and enables better cost management thanks to centralised, accurate data.